Nexeed Automation at Bosch in Ansbach

With Integrated Robotics, robots and machine controls speak the same language

Summary

In the complex production lines of the Bosch plant in Ansbach, robots ensure quality and economic efficiency. However, programming the robots for new lines was anything but efficient: The different programming languages of the robots and their integration into the machine control system involved enormous effort. Nexeed Automation provided a remedy: The Integrated Robotics module significantly simplifies the integration of the robots. The startup of the machines runs more smoothly and, even early on, enables a high degree of utilization - at the same time with fewer rejects.

Nexeed Automation successes at a glance

Reduced programming effort

Control robots from different manufacturers in a single operating panel - thanks to Integrated Robotics

High level of user-friendliness

Machine operators on site can find errors by themselves

Greater than average utilization rate

Plant utilization rate at 82 percent eight weeks after start of production

Initial situation

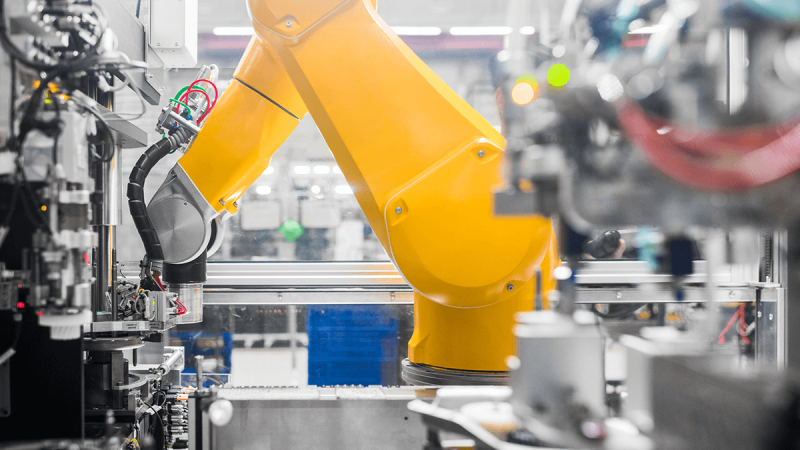

At Bosch's automotive electronics plant in Ansbach, robots from different manufacturers often work together within a production line to manufacture complex components. However, the resulting efficiency is a hard-won commodity, because the programming effort is enormous. Each robot manufacturer uses its own software with its own programming language, in which the programmers must be trained. And the work is not yet done with the programming of the robots; after that, an interface to the machine control system of the plant has to be developed for each of them.

For a new line involving the production of housings for the Boost Recuperation Module - a vehicle component for energy recovery - ten robots from two manufacturers were to be used at the same time. The housing is complex and consists of up to 14 inserts that have to be placed in specific positions in an injection mold. The robots were to be able to produce three product variants at the same time. The programming effort required after the earlier procedure was enormous.

Solution

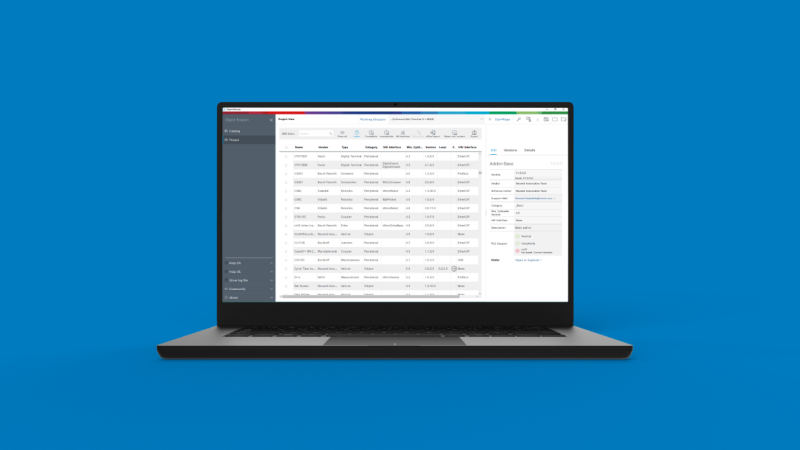

Ansbach turned to Bosch Connected Industry to make the language diversity manageable. "With Nexeed Automation, we can overcome the hard boundary between robots and control technology in Ansbach," explains our Product Manager Benedikt Geissler. Part of Nexeed Automation is also the "Integrated Robotics" module. This allows robots from different manufacturers to be controlled via the plant's central control panel. Experts no longer need to program the robots in their own language. It also makes it much easier to link the robots with cameras and sensors. "The system offers a lot of freedom," says Benedikt Geissler. "Especially the changeover to new product variants or the access to data is noticeably easier. And through the universal interface to all the robots, programmers can set up everything right from the machine controller."

In addition, Nexeed Automation already comes with templates for standard processes such as "pick and place," which significantly speed up programming. This is a welcome advantage, especially when starting up a new plant, where time pressure and tension are at their greatest levels.

Results

The numbers show that the startup of the new line went more smoothly than usual. Just eight weeks after the start of production in August, the line had a utilization rate of 82 percent - greater than average. The reject rate was only around 0.1 percent. At the same time, the experts now have to worry less about the line. Error messages now appear right in the machine control system and not on a separate panel. The operators on site can handle this better and isolate errors by themselves. The technical plant manager is also satisfied with the results: “The project impressively demonstrates our innovative capacity for solutions in manufacturing technology. In this way, we secure long-term competitive advantages in the manufacture of our products - both in Ansbach as well as in our global manufacturing network."

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET