Systematic Production Improvement for Bosch’s Blaichach plant

with software solutions of the Nexeed Industrial Application System

Summary

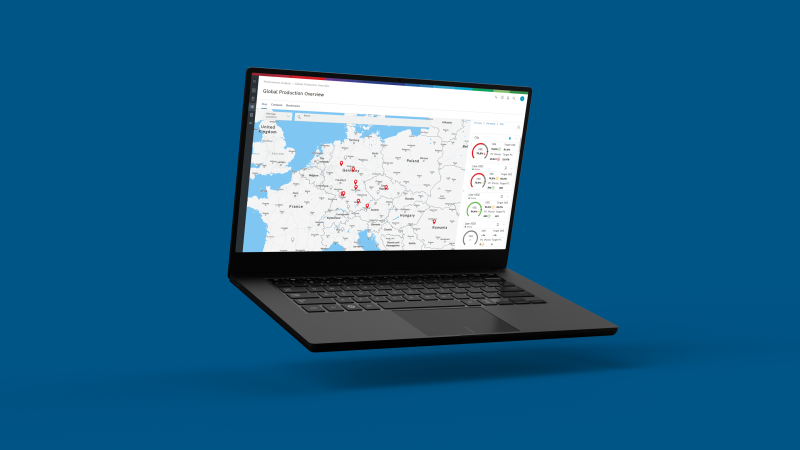

To systematically improve production sequences, the Bosch plant in Blaichach cyclically evaluates new Industry 4.0 solutions along the production value stream and includes suitable solutions into its portfolio. Most recently, several software solutions of the Nexeed Industrial Application System (Nexeed IAS) was added to the portfolio. The applications can be optimally integrated into the production environment and the underlying IT systems. It supplements existing solutions with respect to visualization and evaluation of real-time data. The intuitively operable management interface of the software enables the different user groups to monitor the production and process data of different types of machines within an application in real time.

The successes at a glance

Full transparency

Increased efficiency

Cost savings

One system for various use cases in the plant

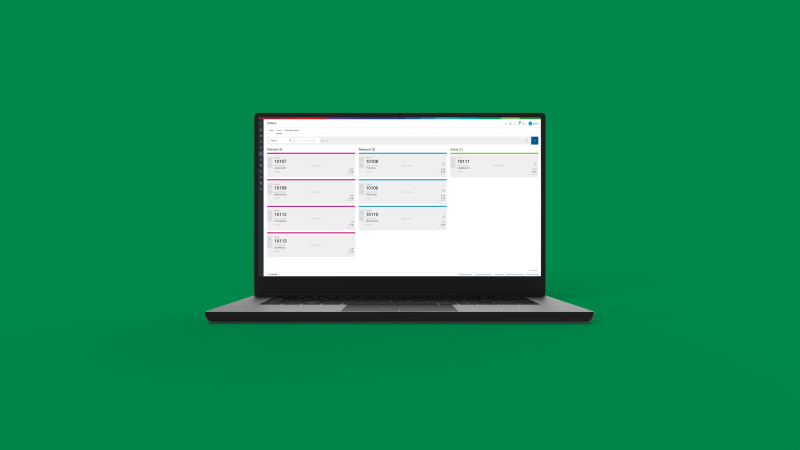

The targeted monitoring of quality-related parameters provides for higher transparency of the manufacturing process and quality. In addition, it supports employees on the line. They receive selected information about deviations through the line management functions (Linecockpit and Linestatus) and can concentrate on the general availability of the plant. The system thus supports the daily work in production, maintenance and quality management.

The software applications of the Nexeed IAS support the Andon boards used for visualizing the output quantities. They enable staff to monitor the cycle times in real time and to identify potential deviations of the target delivery quantities. Line staff are informed quickly and can intervene. This not only shortens reaction times for troubleshooting and simultaneously reduces the number of unplanned maintenance. It also helps in taking preventive measures to proactively avoid errors.

The applications of the Nexeed IAS are, amongst others, suitable for use in exchanging stamping tools: up to now, this was done at fixed predetermined maintenance intervals. This sometimes led to an excess of the threshold force before the next maintenance interval, which in turn was responsible for tool breakage during production and ultimately a higher reject rate. The Blaichach plant now relies on the software to monitor the force of the stamp, as well as its surface in real time. An array of threshold values has been defined for this force value. If this threshold is reached, the solution automatically sends notifications to the responsible machine operator and process experts and conducts additional actions. The gradual approach for threshold value definition makes it possible to create an escalation model based on the criticality of the respective threshold value. The people in charge initiate the appropriate measures that prevent tool breakage.

Software solutions of the Nexeed Industrial Application System for the worldwide plant network

As lead plant, Blaichach is committed to achieving economies of scale in the production network with Industry 4.0 solutions. For this reason, Blaichach has created a standard that makes it possible to identify and evaluate use cases globally throughout all plants. This basic prerequisite has decisively contributed to the successful implementation of Nexeed IAS and to the acceptance of the new solution.

This standard now enables the plants to implement similar or identical use cases more quickly and to exchange experiences in how they are managed. The standard creates a clear understanding of the use cases and provides the necessary transparency in the manufacturing process. The previously developed communication and training concept was also critical for the success of the software applications of the Nexeed IAS. To start with, all participating roles such as process experts, machine operators and maintenance technicians were drawn into the rollout and intensively trained on the line for a real use case.

A “starter kit” specially developed in Blaichach offers comprehensive access to learning videos for properly managing the solution as well as exemplary evaluations of possible use cases in the line. A support concept about key users and experts rounds out the use of the software in Blaichach and in the production system.

Remark on the software solution used: Bosch‘s Blaichach plant is currently using the software solution Nexeed Production Performance Manager. The individual applications Condition Monitoring, Process Quality and Ticket Management are being transferred to the Nexeed Industrial Application System, where they are developed further. The use cases described here can now be realized with the Nexeed Industrial Application System.

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET