Digital Twins

Tap the full potential of data with Digital Twins!

Traceability of products throughout the entire lifecycle

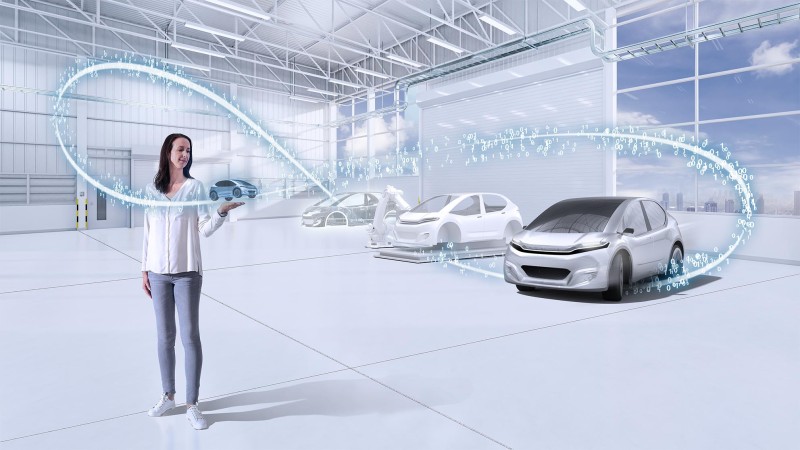

Making the entire lifecycle of a product transparent – that is the goal and, at the same time, the greatest challenge of many digitalization measures.

From development to production, to use by customers, vast amounts of data are generated from a wide variety of sources. Finding this data and making it usable involves enormous effort. This often fails even during the assignment, contextualization and interpretation of raw data outside of its native system. To ensure complete traceability or a complete picture of the entire lifecycle of a product, it is necessary to get this abundance of data under control and to glean value-added, comprehensible and easily retrievable information from it.

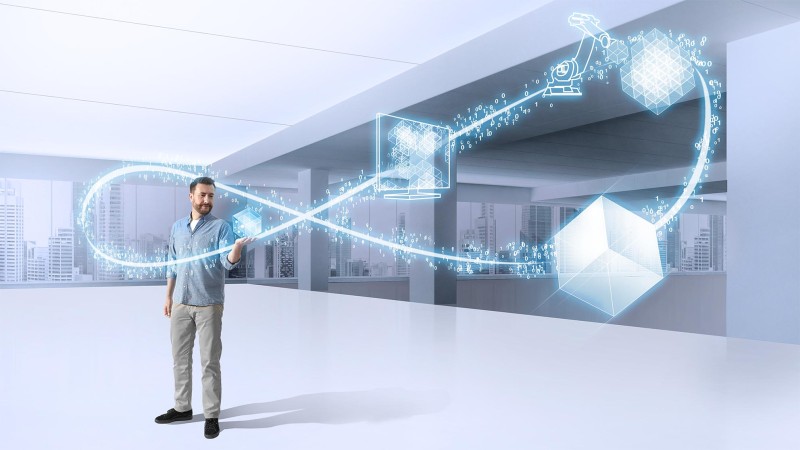

The Digital Twin concept from Bosch Connected Industry addresses precisely these challenges. The principle behind the solution is the combination of raw data and context. A Digital Twin is a digital representative of its corresponding real model, for example, a vehicle component. This allows users from anywhere to find and interpret the contextualized information. Comprehensive data homogenization thus leads to seamless traceability of each individual product, from the first minute of planning up to its use by customers.

The secret behind Digital Twins: semantic data structuring

But how exactly does Digital Twin technology work? Comprehensive semantic data homogenization – which links data to contextual information – forms the core. Let’s take a product from the automotive industry as an example: a motor equipped with sensors constantly generates data that, thanks to Digital Twin technology, becomes generally comprehensible information. This data is grouped according to aspects, e.g. errors or status data. Software tailored to individual user groups assesses these aspects and provides employees with precisely the information they need: technicians need information on errors that have occurred, while quality engineers are more interested in the long-term performance of the motor in order to identify optimization potential. Master data, as well as historical information from the development and production of the particular component, complements the operational aspects from daily use. The semantic description and contextualization itself must be in a machine-readable format – in the case of Digital Twins, the Semantic Aspect Meta Model is the tool of choice.

All of these contextualized data packages are located in the Asset Administration Shell (AAS for short). It ensures cross-manufacturer interoperability and enables authorized users to retrieve unlocked information via API. For example, in the event of recurring problems, quality engineers can track when and where a specific component was installed – and thereby trace back each individual part.

Knowledge graphs allow complex database queries

Accordingly, Digital Twins not only provide an enormous amount of information about the individual product, but at the same time, open the door to an entire ecosystem of connections. However, the further away one gets from the target product during the research, the larger the amount of data that has to be sifted through – for example, when searching for products with a specific configuration and manufactured during the same timeframe. Conventional database systems reach their limits when it comes to dealing with such complex queries; a single missing cross-connection means that important research goes nowhere.

Knowledge graphs address this challenge by establishing relationships between individual objects, thus defining each data packet as a node in a network. The edges represent the relationships between the nodes. The data model behind the graph is called the ontology. It defines the rules according to which the types of data are related to each other, e.g. that a line is part of a production site or that a tire is part of a vehicle. These simple rules can be used to create gigantic networks where database queries run like a plot thread along the connections. The more data and relations from the entire lifecycle of a product that the network contains, the denser it becomes. This means that even complex issues can be clarified at any time and from anywhere, such as whether a particular product component shows similar wear behavior under the same load, or whether a malfunction also affects other products from the same batch.

Bosch as a driver for open standards in the connected industry

The full potential of semantic data homogenization can only be tapped through cross-company collaboration: an open-source approach makes the technology available to everyone, creating a space for synergies and new, data-driven business models. Small and medium-sized companies can thus operate on equal footing with international corporations. Together, they can also address the important issues of the future, such as resource conservation and climate protection throughout the lifecycle.

Therefore, Bosch is involved in the four leading initiatives on the topic of data homogenization or semantic stacks:

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET