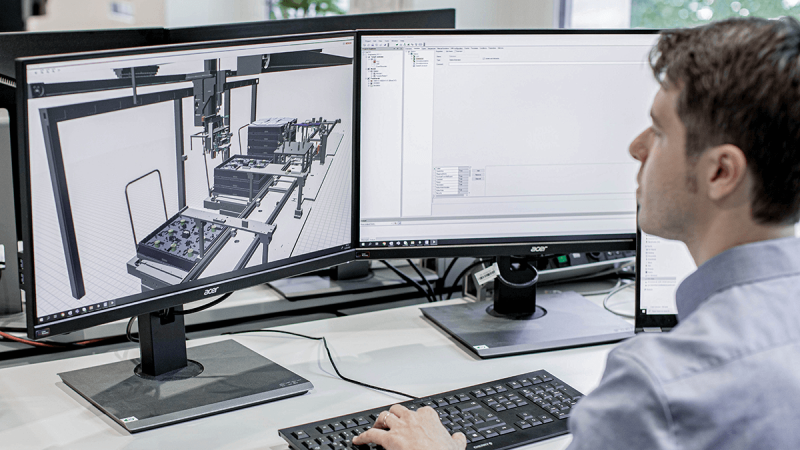

Engineering

PLC Code and HMI

The control-independent basic system Control plus offers a consistent, innovative and future-proof software system for all phases of the machine life cycle: From project planning, control configuration and visualization to motion control, safety connection, simulation, start-up, connectivity and diagnostics up to comprehensive service for machines and systems in production.

What is Control plus?

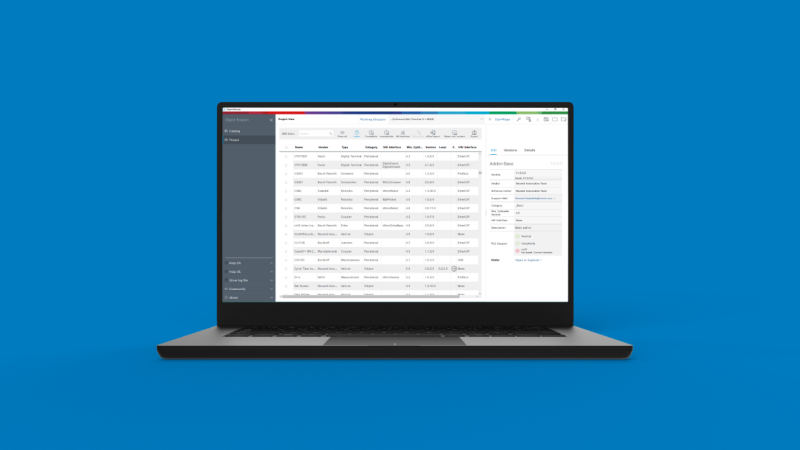

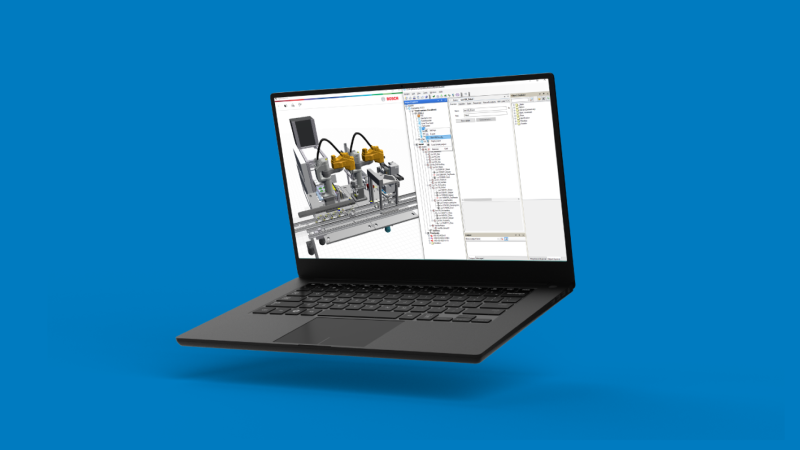

Control plus is a particularly user-friendly development environment for modular engineering. Our controller-independent software system Control plus offers an engineering environment based on modular design, provides user-friendly, standardized user interfaces and networks your machines easily and efficiently. You can expand the basic system at any time depending on your needs and requirements: Various technology packages for the areas of robotics, dispensing and image processing are available. Our 3D simulation environment also enables virtual start-up, which significantly reduces machine cycle times. Machine apps and analysis options are also available for your projects.

Who is Control plus for?

PLC developer

Mechanical engineering

Production and logistics companies

What do our customers say?

Peter Klöpfel, Board of Management/ CEO Eberhard AG

How does Control plus work?

Everything at a glance

Over 100 machine manufacturers already work with Control plus

Our system can be operated with Rexroth and Beckhoff

We support control systems from Rexroth and Beckhoff.

ctrlX AUTOMATION from Rexroth overcomes the classic boundaries between machine control, the IT world and the Internet of Things. With the real-time-capable Linux operating system, open standards throughout, app programming technology, web-based engineering and a comprehensive IoT connection, ctrlX AUTOMATION reduces component and engineering costs.

FAQ

Beckhoff and Rexroth

IEC 61131

Yes, this is possible. We offer training for this. Please do not hesitate to contact us.

If you have questions

Martin Mayer

Account Manager

Mobil +49 152 02139000

Get in contact

Werner Cramer

Account Manager

+49(711)811-58878

Get in contact

Maximilian Albrecht

Account Manager

+49(711)811-45514

Get in contact

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET