Efficient energy management in 3 steps – Sustainability in manufacturing

Saving natural resources has become more crucial than ever. Prices are rising, and climate change puts the entire economy at risk. At the same time, industry is one of the main energy consumers. While we cannot shut down our factories, we can make a very important contribution to sustainability efforts. What it takes is a proven, strategic approach to efficient energy management. Join us on the Bosch path and find out how factories of every size can contribute to a more sustainable future in connected manufacturing with a three-step approach.

Step 1: create a valid database with Industry 4.0 software

It is crucial to know which process, machine, or product consumes which amount of energy. Accessing this data already presents the first major challenge: older systems are a kind of “black box” and often do not provide the data in its required depth. Sensors and communication modules must make sure that all data is sent to higher-level systems. Intelligent energy management software consolidates the existing data and shows information gaps. Together with a step-by-step retrofitting of existing systems, it can display entire processes clearly and consistently to define the relevant key figures. The investment quickly pays off: the software compares performance, network quality, and operating status of entire lines with the actual values or targets. Depending on the degree of automation, it can even control the systems in real time to avoid peak loads.

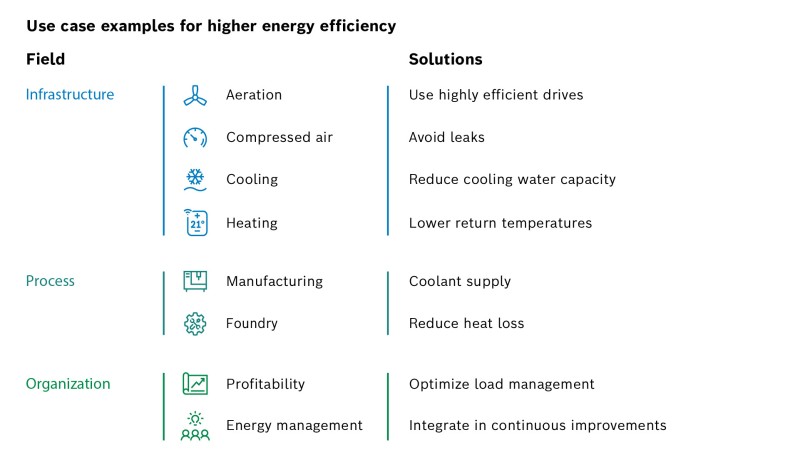

Step 2: identify use cases methodically

Whoever wants to achieve long-term energy goals should not only tackle specific projects but perform a methodical cost-benefit calculation. It considers the new key figures, their strategic weighting, and the expected energy price development. Moreover, it defines both goals and the greatest cost drivers right down to the product level. Measures and focus areas can be prioritized depending on deviations. Identifying use cases within the focus area should also follow a methodical procedure: an interdisciplinary team, consisting of local process specialists and experienced energy efficiency experts, can analyze the value stream and carry out on-site inspections. Once a use case has been defined, the team establishes an implementation concept and defines short and long-term goals and milestones.

Step 3: implement continuous improvement processes

Apart from defining concrete projects, it is even more important to implement energy efficiency in daily work by defining goals and committing all persons involved to the new process. Hence, the next step consists in communicating the reasons, advantages, and objectives of the change to all associates. Just like in lean management, measures should now be developed continuously towards optimum effectiveness. Skilled workers and management are the drivers of this constant improvement. Technically, a solid data base is required to achieve the defined goals through permanent readjustments and to check the effectiveness of implemented projects. The analysis of any deviations from the forecasted savings provides valuable information for subsequent projects.

Conclusion

Efficient energy management is a crucial step for companies to become more sustainable and counter the challenges of climate change. Bosch has been committed to consistent environmental management for years and is aiming to achieve further energy savings of 1.7 terawatt hours by 2030. This corresponds to more than a fifth of current annual consumption. By connected manufacturing and using Industry 4.0 technologies, companies can increase their energy efficiency and reduce costs at the same time. And thus contribute to greater sustainability and climate protection. A strategic approach and the methodical identification of use cases enable factories of all sizes to do their part towards a more sustainable future. Efficient energy management is therefore not only ecologically sensible, but also economically beneficial.

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET