Bosch Connected Industry starts cooperation with PEM chair at RWTH Aachen

As part of the EU Green Deal and the Circular Economy Act, new legal frameworks are emerging that increasingly aim for transparency and sustainable action. These attributes are also becoming the focus of strategic and operational business for economic players. This can result in the desired decarbonization of industries as well as efficiency gains along the value chain.

The goal of this legal change is to steer the economy towards sustainable practices. In order to meet the legal requirements and enable sustainable and more efficient business practices, Bosch Connected Industry has entered into a cooperation with the chair of Production Engineering of E-Mobility Components (PEM) at RWTH Aachen University in the areas of “Traceability” and “Digital Battery Passport”. The collaboration started at the end of 2023 and will gain momentum over the course of this year.

Digital twins promote traceability, digital battery passport, and PCF determination

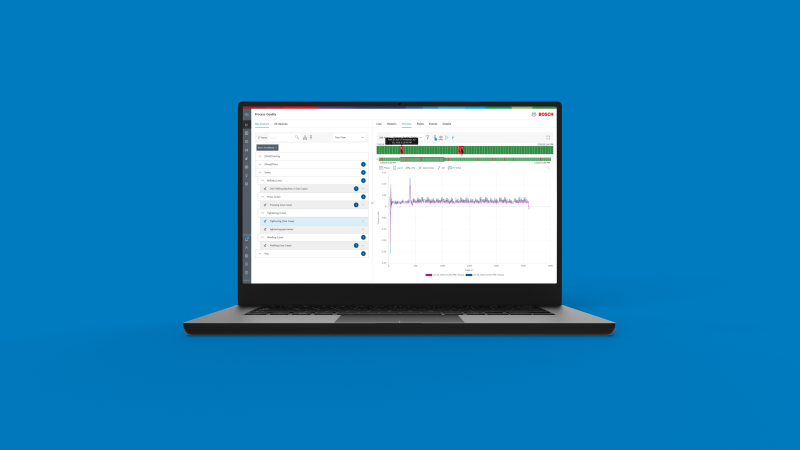

The cooperation focuses on traceability and sustainability. The digital battery passport will contain data on every battery, including its supply and value chain. Digital twins will make it possible to collect, evaluate, and trace this data from battery cell production in a targeted manner. In future, certain sustainability factors, including the product carbon footprint (PCF), will be recorded for each battery cell to create full transparency of the supply chain and its emissions.

However, targeted product traceability in manufacturing is complex and complicated due to the combination of different processes. Hence, the project is all about developing concepts and applications that tackle this problem. Sufficiently precise traceability makes it possible for the first time to analyze interactions between the individual process steps in a structured manner and increase process stability in the long term. A traceability system for battery cell production that is optimally tailored to the process requirements contributes to more sustainable and efficient production. In addition to the desired sustainability, quality, safety, and cost-effectiveness are always ensured.

Achieving more together

By pooling skills and expertise from research, development, and practical implementation, we want to create initial concepts for the digital battery passport and traceability to support you in achieving sustainability goals.

We look forward to the next steps in this cooperation and will of course keep you updated!

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET