Bosch Power Solutions

Global transparency thanks to the Nexeed Industrial Application System

Summary

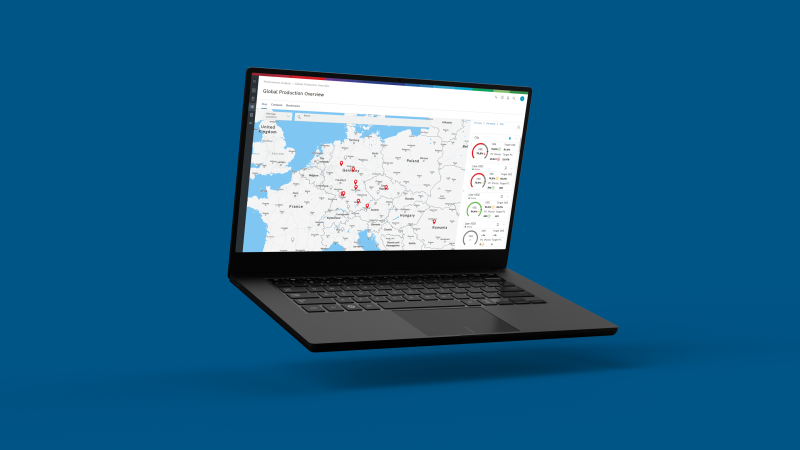

Permanent optimization requires one thing in particular: transparency. Bosch Power Solutions obtains this for more than 550 lines in around 30 plants – amongst others thanks to the Global Production Overview application from the Nexeed Industrial Application System. Comparisons of key production indicators and comprehensive reports make it possible to identify and transfer best practices in the international production network.

The successes at a glance

Comparison of all KPIs from the production lines

for a global overview and identification of optimization potentials

Identification of best practices

and transfer to other lines in the production network

Ideal management tool

as a basis for cost-reducing decisions

Background

Production managers and their superiors depend on transparent information to continuously optimize processes. But how can they find out which manufacturing processes are most efficient in the global production network? And how should the large amount of data be presented to enable those in charge to draw the right conclusions? Among other things, Bosch Power Solutions relies on the Global Production Overview application from the Nexeed Industrial Application System – currently for more than 550 lines in around 30 plants all over the world.

Solution

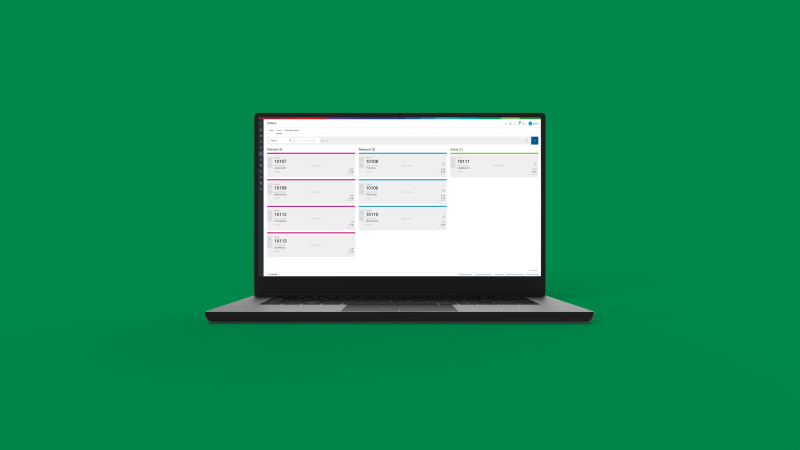

Like the entire Nexeed Industrial Application System, the Global Production Overview application was developed out of a specific need. In this case, Bosch Power Solutions required a tool that would allow production and plant managers to compare their lines across the global production network. The application provides a quick overview of standardized key figures. Reports as well as KPIs such as OEE, number of units, utilization or failure rates can be displayed across all locations. Sorted by business unit, product group or location and limited to selectable time periods, the status of the KPIs can be clearly displayed down to line level in a bar chart or a spreadsheet.

This allows managers to see immediately how their lines are performing around the world. It is easy to identify best practices, and to transfer the newly gained knowledge to the other lines. New lines in the factory network are also easy to integrate. During ramp-up, the application further provides the data basis that is needed to ensure smooth processes and reduced costs. Another positive side effect: to make the lines comparable within the software, the names of lines and products have been standardized globally, which has helped make the entire organizational structure more transparent.

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET