Bosch Rexroth: Condition-based maintenance for hydraulic test stands

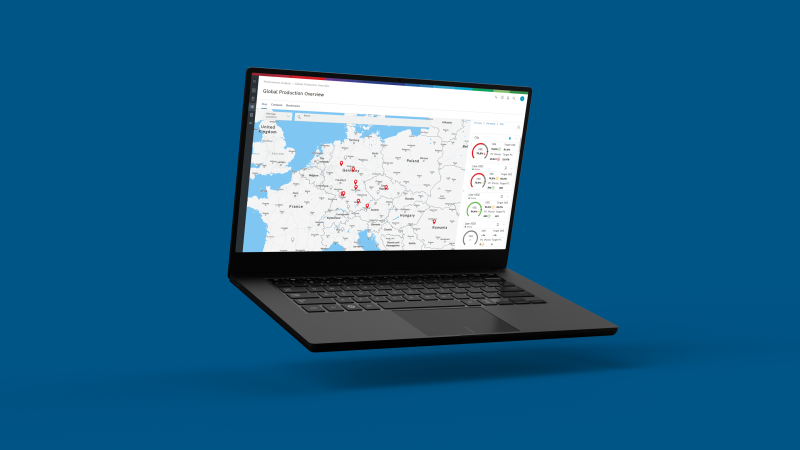

with software solutions of the Nexeed Industrial Application System

Summary

Bosch Rexroth AG, a Bosch company, is one of the leading specialists in drive and control solutions worldwide. Hydraulic controls, along with the accompanying electronic units for use in mobile applications in agricultural technology and industrial hydraulics, have been produced at the Homburg/Saar plant in Germany since 1965. The digitization of production is a matter of course for Bosch Rexroth in times of ever higher customer demands. This also applies to the efficiency increase and quality assurance of hydraulic test stands – a classical retrofitting job that Bosch Connected Industry was happy to take on.

Several applications of the Nexeed Industrial Application System (Nexeed IAS) monitor the condition of hydraulic oil at the test stands. Harmful particles in the oil that could cause damage to the test specimen and test stand are now immediately recognized. What’s more, the software solutions continuously visualizes the oil condition and sends a notification to maintenance technicians in the case of deviations in quality. Fixed maintenance dates can thus be replaced by Predictive Maintenance, which not only saves costs and raises quality, but also prevents system downtimes caused by contamination. In this specific case, system effectiveness was increased by 5%.

The successes at a glance

Significant OEE increase

5% higher system effectiveness, above all through the reduction of unplanned downtime

Lower maintenance costs

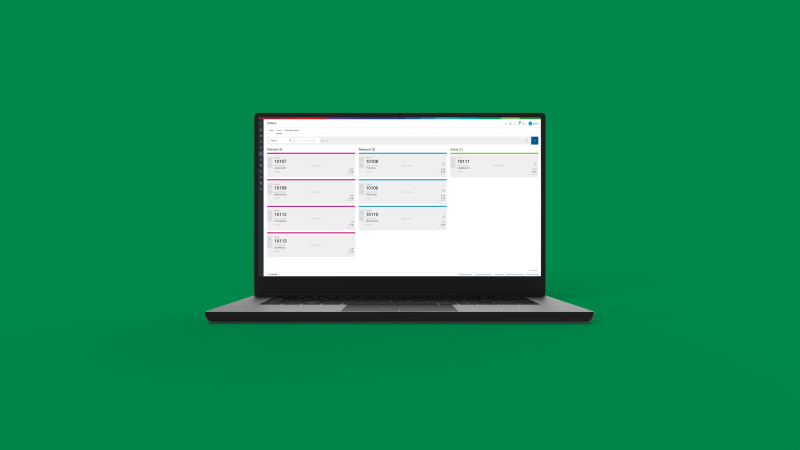

Condition-based maintenance and faster reaction through automated ticket generation

Optimized quality

Continuous monitoring and documentation of filter status and oil quality

Background

At the Homburg/Saar plant, Bosch Rexroth manufactures, amongst other things, valves for hydraulics in mobile machines such as tractors. The company is a worldwide leading specialist; hence its production is subject to the most demanding quality standards. The fully assembled valves are checked for tightness and adjusted to electronics at a total of 30 test stands. But despite the cleaning of the valves beforehand, the smallest metal particles, metal filings or residual water could end up in the hydraulic oil used at the test stand – and thus cause damage to the test specimen and test stand. As a result, system downtimes caused by contamination comprise around 25% of total downtime costs.

For a long time, the plant relied on fixed maintenance intervals to avoid downtime. The filter media was changed at regular intervals, regardless of actual levels of contamination; the test oil was examined on a weekly basis for dirt particles; the oil purity on the tank side was checked in 3-month cycles.

If contamination occurred shortly after this inspection, however, the test station would continue to run with dirt particles in the oil until the next maintenance date. Besides the contamination of test specimens and threat of downtime, reduction in quality with a corresponding increase in reworking were further consequences.

Bosch Rexroth therefore decided to collaborate with Bosch Connected Industry. Various applications of the Nexeed IAS for increased efficiency proved to be the ideal solution for the digitization of already existing systems – with the goal of increasing the availability of test stations and implementing predictive maintenance through continuous hydraulic oil monitoring.

Solution

All hydraulic test stands were quickly retrofitted with the appropriate hardware. The Industry 4.0 experts installed a total of 20 IoT Gateways from Bosch Rexroth and a wide variety of sensor types with high connectivity. These sensors measure particles found in the oil, water content and temperature. The data needed to assess the oil purity and condition passes through the gateways into the software system. Additionally, pressure sensors attached to oil filters deliver valuable information about the degree of contamination in filter cartridges.

The software bundles and visualizes this data on all mobile devices. Maintenance technicians see all of the important parameters at a glance. If the software registers water in the oil, for example, this can cause oxidation and then rust on machine parts. The employees in charge can now intervene early on and exchange the hydraulic oil before damage is done to the equipment. They also immediately recognize harmful particles in the system and can prevent the contamination of further test specimens.

In addition to higher process transparency, rules for established parameters can be created by employees, even without programming knowledge. If a value exceeds a defined limit during test oil monitoring, the ticketing system integrated into the software immediately sends a message to the responsible maintenance technician. For example, the software generates an e-mail message in the case of filter wear. The technician can now perform the filter change when it is truly necessary, rather than after a designated period. This conserves material and prevents unnecessary maintenance appointments and system downtimes.

Positive results were already visible and quantifiable shortly after the software implementation. Internal calculations revealed that maintenance costs at the test stands could be reduced by around 25%. System stoppages previously caused by contamination that was not immediately detected were also reduced, which resulted in an OEE increase of 5%. The one-and-a-half years predicted by the Homburg plant for the amortization of total costs for retrofitting could in all likelihood be fulfilled.

Outlook

The initial success led to implementations of further applications of the Nexeed IAS. For example, an application in the Condition Monitoring area has already been implemented. In combination with the Bosch Energy platform, the energy consumption of machines can be monitored in order to draw conclusions regarding their condition. Furthermore, the software now allows for better compressed air efficiency: leakages are identified more quickly, thus saving costs. Use of the software is also anticipated in spindle monitoring, tool changing and cooling lubricant management.

Remark on the software solution used: Bosch's Homburg 2 plant is currently using the software solution Nexeed Production Performance Manager. The individual applications Condition Monitoring, Process Quality and Ticket Management are being transferred to the Nexeed Industrial Application System, where they are developed further. The use cases described here can now be realized with the Nexeed Industrial Application System.

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET