Control plus – technology packages

Intelligent function extensions for maximum efficiency

The great variety of automation technology leads to complex and heterogeneous control topologies: For example, subordinate subsystems are often used in image processing, robotics or measurement technology. However, these only rarely offer the possibility of taking over information or engineering data from the control technology.

In addition, the systems require a great deal of expertise: Both in engineering as well as in machine operation, specialized staff are needed on a permanent basis. Control plus offers a more efficient solution with intelligent function extensions. These can be easily licensed via software on the automation system and are directly connected to the runtime system, the visualization and the engineering data.

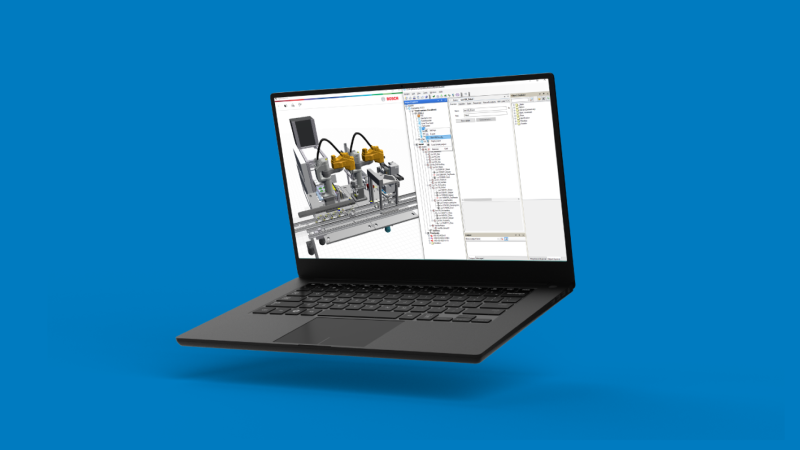

Thanks to Integrated Robotics, even robots from different manufacturers speak the same language, which minimizes programming effort.

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET