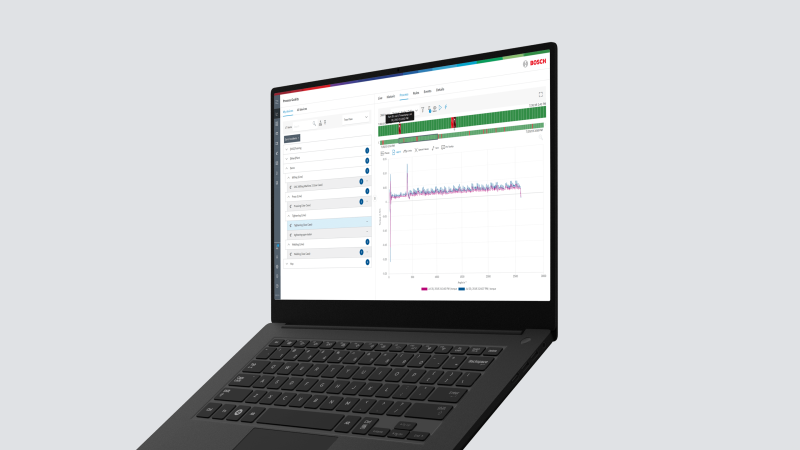

Process Quality

Optimum process monitoring in manufacturing

Higher process transparency and quality in ongoing production

Benefits at a glance:

Process transparency

thanks to user-friendly provision of all process data

Optimum increase in efficiency

thanks to analysis functions for systematic error detection

Save costs

by reducing scrap, rework, and product recalls

Higher product quality thanks to higher process transparency

The Process Monitoring module generates a high level of transparency in production. It helps process and quality engineers to improve the efficiency of their production step by step. Live process data monitoring with the user-friendly cockpit enables them to have everything in view in real time.

Various measurement values and tolerances can be visualized as required. This way, measures can be taken quickly, and not only when problems occur. Thanks to patented analysis functions, systematic errors are detected earlier, and causes are narrowed down – allowing for a response before e.g. rejects occur. The Process Monitoring module is particularly suited for obtaining transparency of joining and coating processes.

Main functions of Process Quality

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET